Publisher: Release time: 2016-04-26 Times of browsing: 5474

Overview

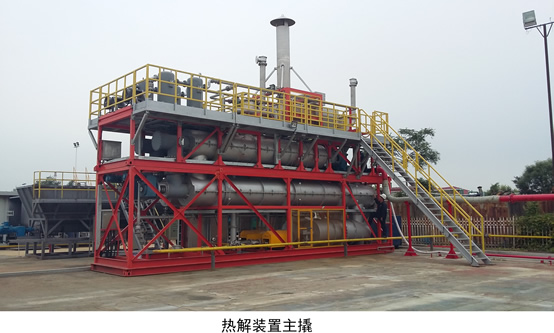

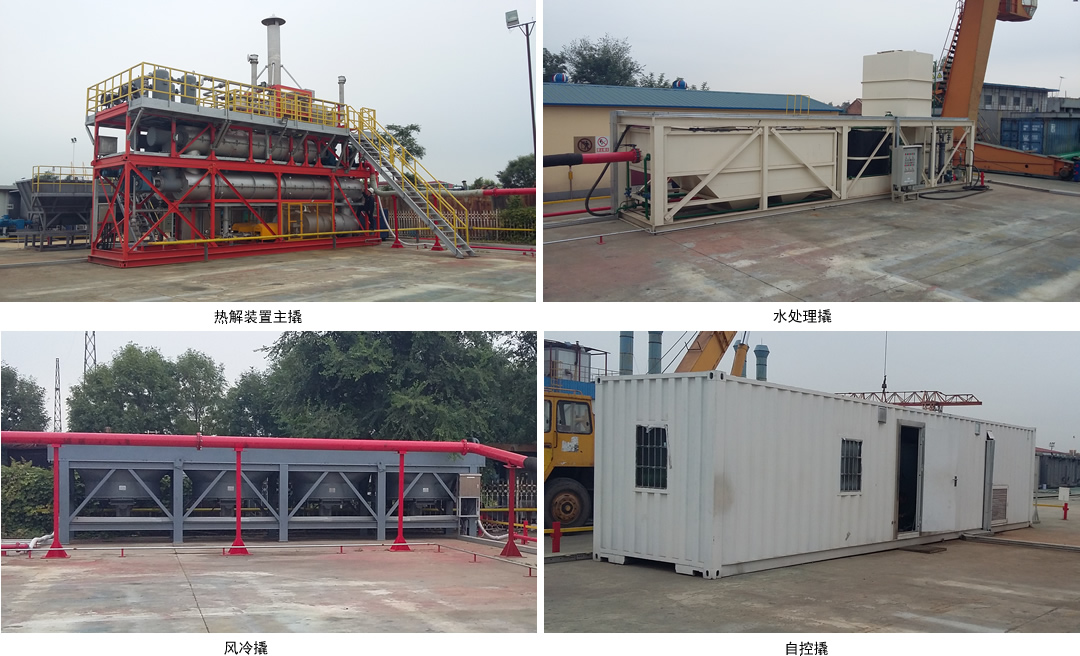

The oily sludge thermal desorption equipment isan independently developed system of our company for oily sludge non-hazardoustreatment. Adopting the principle of high temperature gasification, oily solidsare externally and indirectly heated to 600℃, a temperature at which components ofhydrocarbon are vaporized and separated from solids. The vaporized oil and gas aresubsequently cooled down and undergone a recycling treatment process. Theequipment is mainly used for non-hazardous treatment of oily sludges.

Features

1、Treatment capacity: 2m³/h(3 t/h)

2、Indicators for thedischarged material:

Oil(TPH) content in the solids: <0.3%;

Water content in oil: <2%<>

Oil content in water: <10ppm<>

3、Indicator references forthe feeding material:

Oil content in the sludge: ≤15%;

Water content in the sludge: 1-60%(a lower water content can savethe amount of fuel consumption)

4、Heating method ofthermal desorption: closed hot air heating

5、 Pyrolysis pressure: Slightlypositive pressure;

6、Pyrolysis heatingtemperature: 300-600℃;

7、Fuel type: Natural gas;

8、Footprint: Fixedstation, 1500m²(30meterX50meter);

9、PLC programming automatic control

Advantages

1、Achieving non-hazardoustreatment of oily sludges, the discharged solids can be used for brick-makingand road-mending.

2、Indirect heating, noopen flame is contacting the feed, safe and reliable.

3、An overallexplosion-proof design, and an inert gas shielding system equipped.

4、No leakage of pyrolizedgas, which can be processed to output light oil and clean gas fuel.

5、The revolving speed ofthe equipment is continuous and adjustable so as to ensure the quality ofdischarged residues.

6、The system is equippedwith anti-coking devices, enabling non-coking and non-adhering on equipment wallfor a variety of oily sludges.

7、The system does notdischarge polluting smog, causing minimum environment pollution.

8、The equipment isskid-mounted, easy to transfer or dismount.

9、The system adopts continuous operation mode.

Application fields

1、The system is mainly used for non-hazardous treatment ofoily sludges produced in petroleum and chemical industries. After treatment,the discharged residues can meet the requirements of bricking-making,road-repairing and landfilling.

2、Oily sludges produced inpetroleum and chemical industries include: tank bottom sludges of gathering andtransportation stations in oil extraction plants, oily sludges aftercentrifugal volume reduction treatment, low-water-content sludge in oily sludgepools, oil-based drillings produced in well drillings, landing sludges, sludgeand landing sludges in refineries.

3、The system can also be applied to residuetreatment in a variety of industries, such as chemical engineering, printingand dyeing, coal gas chemical engineering, garbage disposal. After treatment,solid wastes can meet discharge standards.

Floor 19,Block C,Caizhi building,No.18 Zhongguanchun Donglu,Haidian District,Beijing,China

Floor 19,Block C,Caizhi building,No.18 Zhongguanchun Donglu,Haidian District,Beijing,China (+86)010-82600968/0698

(+86)010-82600968/0698 weilun@biotechina.com

weilun@biotechina.com  (+86)010-82600069

(+86)010-82600069