Publisher: Release time: 2019-04-25 Times of browsing: 892

TechnologyOverview

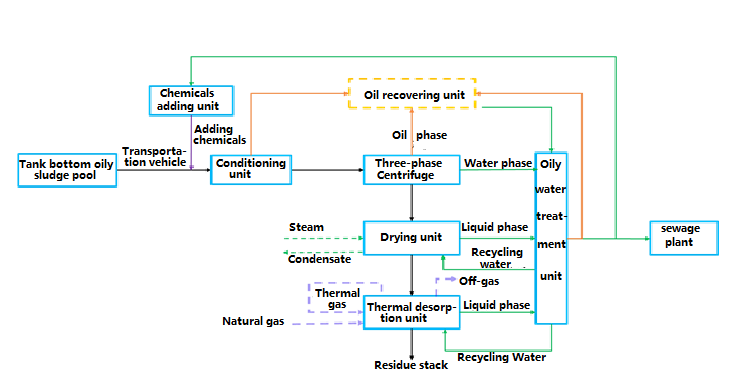

Mechanical pretreatment, chemical heating andconditioning as well as centrifuge separation treatment are adopted to tankbottom oily sludge for volume reduction treatment and oil and water recycling; aftercentrifugal treatment, the oily cake then goes through a drying-up process andthermal desorption treatment for further recycling and hazard-free treatment,through which oil is recovered and solids reach hazard-free requirements.

Technicaladvantages

Ø Flexiblecombination of volume reduction and thermal desorption processes, can meetvarious oily sludge treatment requirements of project owners, and can also becoupled with other similar technologies for technical improvement andupgrading.

Ø Highly automaticand operational, easy maintenance. Able to meet volume reduction treatmentrequirements of high-liquid-content tank bottom sludge and oily sludge pool oilysludge.

Ø The thermaldesorption unit adopts an air starvation environment to indirectly heat organicsolid wastes, from which organics are evaporated and pyrolyzed. Highvalue-added oil and gas products can be obtained, achieving classified andquality-divided resources recycling of organic solid wastes treatment.

Ø The thermaldesorption equipment, according to processing capacity, can be designed as askid-mounted or fixed-station type, meeting diversified needs of differentfeeding materials, processing capacities, site conditions, etc.

Ø Three-phaseproducts gas, liquid and solid are produced from pyrolysis, achievingenvironmental protection treatment and resources reutilization. Oil isrecovered, non-condensable gas is reused, water is recycled and solid dischargecan meet requirements.

Applicationfields

Suitablefor volume reduction, recycling and hazard-free treatment of tank-bottom oilysludge.

Tankbottom oily sludge is mainly found in the first and last stations of oiltransportation, and also in oil storage tanks of oil refineries. Duringretention period, various impurities in crude oil, including inorganic solids suchas asphaltenes, paraffin, entrained soil, sand and gravel, settle freely undergravity, forming tank bottom oily sludge. The presence of tank bottom oilysludge not only occupies tank space, but also causes waste of crude oilresources.

Floor 19,Block C,Caizhi building,No.18 Zhongguanchun Donglu,Haidian District,Beijing,China

Floor 19,Block C,Caizhi building,No.18 Zhongguanchun Donglu,Haidian District,Beijing,China (+86)010-82600968/0698

(+86)010-82600968/0698 weilun@biotechina.com

weilun@biotechina.com  (+86)010-82600069

(+86)010-82600069