Publisher: Release time: 2019-04-25 Times of browsing: 1087

Technologyoverview

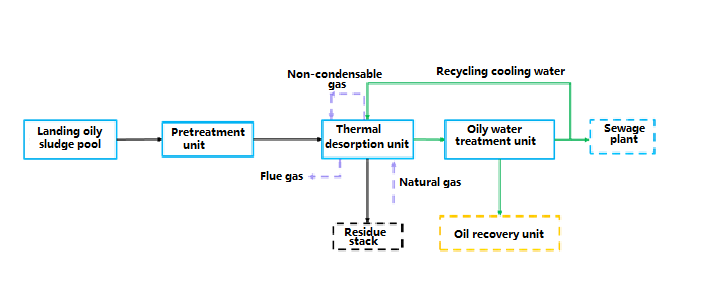

Pretreatmentand thermal desorption processes are adopted to landing oily sludge forresource recycling and hazard-free treatment, through which oil is recoveredand solid residues meet hazard-free requirements.

Technicaladvantages

Ø Highly automaticand operational; easy maintenance

Ø The thermaldesorption unit adopts an air starvation environment to indirectly heat organicsolid wastes, from which organics are evaporated and pyrolyzed. Highvalue-added oil and gas products can be recovered, achieving classified andquality-divided resources recycling from treating organic solid wastes.

Ø The thermaldesorption equipment, according to processing capacity, can be designed as askid-mounted or fixed-station type, meeting diversified needs of differentfeeding materials, processing capacities, site conditions, etc.

Ø Three-phaseproducts gas, liquid and solid are produced from pyrolysis, achievingenvironmental protection treatment and resources reutilization. Oil isrecovered, non-condensable gas is reused, water is recycled and solid dischargecan meet requirements.

Applicationfields

Suitablefor treating landing oily sludge. Landing oily sludge is formed during oilfield oil extraction, oil transportation, etc. by mixing landing crude oil withsoil, sand and water, etc. Landing oily sludge is a mixture difficult to beseparated. The oil content in landing oily sludge is around 10%~30%, and after insolation andweathering, light components in oily sludge are further reduced whileimpurities in heavy components are further increased, causing difficulties inseparation.

Floor 19,Block C,Caizhi building,No.18 Zhongguanchun Donglu,Haidian District,Beijing,China

Floor 19,Block C,Caizhi building,No.18 Zhongguanchun Donglu,Haidian District,Beijing,China (+86)010-82600968/0698

(+86)010-82600968/0698 weilun@biotechina.com

weilun@biotechina.com  (+86)010-82600069

(+86)010-82600069